- +91 124 2398037

- sales@ambadi.murugappa.com

As a part of our constant research, our design team is constantly looking at new trends, colors, methods/processes, and weaves throughout the year in order to establish new constructions and finishes. To keep them engaged, we encourage them to travel the world and attend exhibitions and events all over the world to gain a deeper understanding of regional designs, colors, and patterns. By combining these insights and experiences, our designers create state-of-the-art collections and ingenious designs with a commitment to excellence.

Our marketing and merchandising staffs are constantly working to make sure that our client’s orders are properly managed at every stage. Their roles span the entire process, from sample submissions to offer development to production and shipping follow-up, ensuring that all steps are carried out promptly to ensure orders are delivered on time and according to the specifications and we always have a senior personnel available to meet with the clients.

From weaving to printing, stitching to inspection, our production team puts together the stages that lead to the final product. This team consists of highly skilled and acclaimed professionals who are experts in their field. This dedicated team works closely with other departments ensuring timely delivery by making sure that all the component processes associated with the production are finished on schedule.

Yarn preparation firms the seal of carpet making. Our yarn inventory is managed in a way such that the running yarns are always available in stock. This helps in increasing the efficiency of the carpet production process. In our yarn store, a separate area is dedicated to stock the yarns from where our special customized rugs are made within 30 to 45 days. We have a huge range of natural as well as synthetic yarns to create beautiful rugs. The first step in preparing carpet yarn is to wash them. This ensures in removing of any dirt or impurities that might be present, and it also helps to set the dye in the yarn so that the color will be more fade-resistant. After the yarn is washed, it is then dried and combed to remove any knots or tangles.

The yarns are dyed using in-house dyeing which are environment friendly. Depending on the volume, this process might range from vats to jiggers. We ensure that all dyes that are used comply with the international standards and are authorized for commercial usage. Each lot is tested for color fastness to rubbing wet/dry, washing, and light. We make sure the colors correspond to what our customers have requested..

The weaving process is an important part of carpet and rug manufacturing, as it is what that gives the fabric it’s strength and durability. We can quickly produce fabrics with any sort of weave using a variety of machines, whether they are jacquard, plain, dobby, or other. Our weaving facilities are based in Kannur, where we have access to automatic, special, and even basic traditional looms. Use of the same depends on the size, level of quality, and type of weave required for production.

Latex technique is also known as serging, and it's a simple way to finish the carpet and give it a professional look. The application of latex adds strength to the carpets. It’s necessary especially for handloom and hand tufted carpets. Carpet backing is often done to seal the back of a carpet, preventing it from unraveling or fraying.

Once the carpet is latexed and sundried, they are inspected by our quality inspector at a first level. They undergo finishing and surface embellishment like edge finishing, carving and embossing to give the ultimate desired look. The colorful tassels and fringes give a soft touch to our rugs. The final assembly of the product occurs at this step, where a group of expert tailors toil under the supervision of quality controllers who continuously conducts inspections to ensure that the quality standards are being met.

All products are inspected as soon as they finish their processes, from dyeing to stitching, to ensure the quality of the final product.

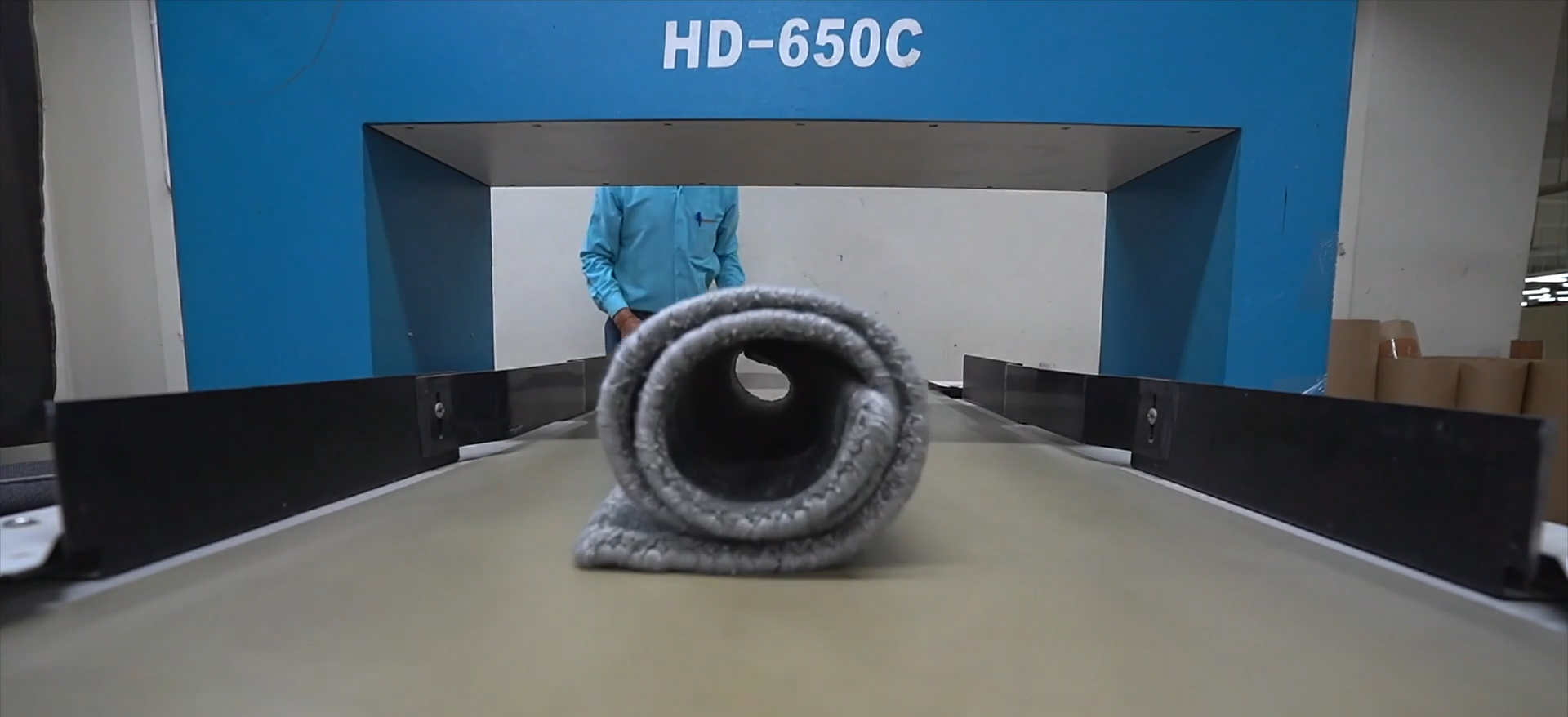

Our Supervisors oversee the entire process and make sure that the apt packing techniques are used, as well as that the correct labels, hang tags, and barcodes are in place. They also make sure that the products are packed in export-ready cartons in accordance with the packing instructions provided by the client. The consumer chooses a method for shipping the packed home goods from the port or airport of their choice. Our team provides timely shipping and customs documentation assistance to ensure the shipment of goods happens on time. While we have qualified clearing and forwarding service providers who have earned our trust, we are also open to working with those whom the clients choose.